Drive digital transformation with the Planview Adoption Framework

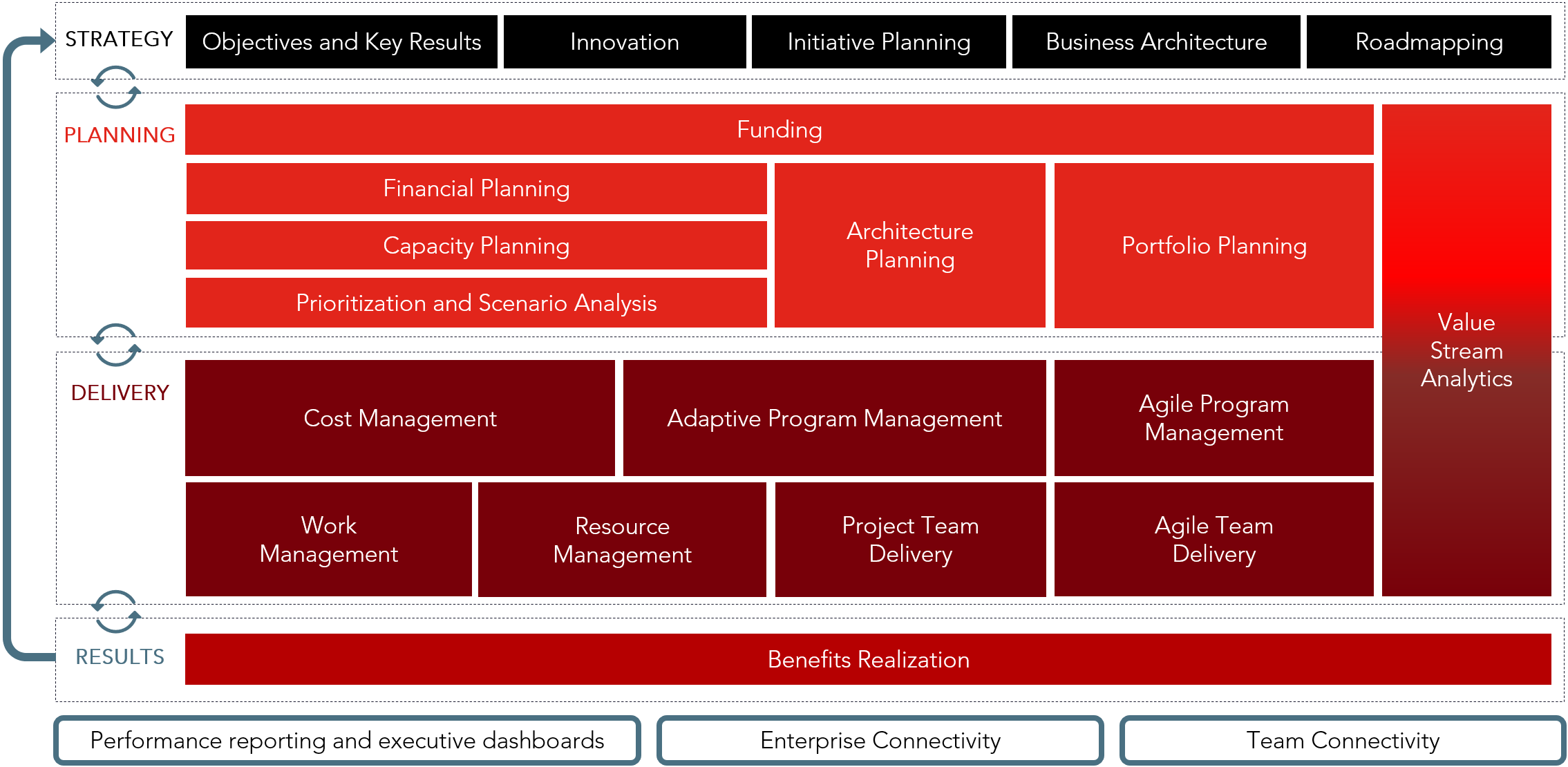

Drawing on our direct experience implementing our solutions for customers in a variety of markets and industries, we designed the Planview Adoption Framework: a series of self-guided customer journeys aligned to each of Planview’s solutions.

Our flexible framework enables leaders to understand which capabilities can be leveraged to achieve their desired business outcomes, no matter what stage of transformation their organization is in. Each capability includes key resources, such as best practices and detailed business processes, to help prepare your teams and get the most value from the Planview platform.

Watch platform demoView solutionsExplore capabilities

Featured Event

Planview Accelerate global virtual conference

Join the largest gathering of Planview customers, industry leaders, and experts to network virtually and level up your skills! Gain actionable information you can use immediately, in day-to-day activities and future planning – reinforcing the benefits of your investment and partnership with Planview.

Planview announces two big innovations at Accelerate

Planview Copilot is a generative AI assistant you can use to converse and question your enterprise data using natural language. It is now easier than ever before to glean insights, derive recommendations, and facilitate work-oriented actions.

Planview.Me is a new actionable and personalized user experience. With Planview.Me, you can customize your Planview experience to highlight the data and details you need to get work done.

Want to know more about how Planview is using AI to build the future of connected work? Check out these exciting programs for Planview Copilot and Planview.Me below.

Webinar

WebinarAI strategy and Planview Copilot webinar

Learn to leverage AI-powered insights, hear about Planview’s vision for the future of AI, and get a demo of Copilot, Planview’s generative AI assistant.

Register now Inner Circle

Inner CirclePlanview Copilot Inner Circle

Contribute your insights and shape the future of Copilot, and get a front-row seat to explore Planview’s AI capabilities firsthand.

Register now Inner Circle

Inner CirclePlanview.Me Inner Circle

Share your input and shape how the Planview.Me connected platform experience grows over time, and get more information about initial functionality.

Register now Program

ProgramGenerative AI Early Access program

Contact your CSM, AE, or Flow Advisor to discuss qualification, availability, and pricing. Currently available to Planview Viz customers, with support for other Planview products coming soon.

New and trending

Video

VideoPlanview platform executive overview

Learn how the Planview platform for connected work is your key to successful digital transformation.

Learn more

Report

ReportTurning strategy into reality

Uncover the actions you need to take with a new study by Economist Impact, commissioned by Planview.

Learn more Product release

Product releaseConnected OKRs

Leverage the connected OKR framework to gain alignment and visibility of objectives in Planview Portfolios and Planview Agileplace.

Learn more